It means you should always consider your customer's needs when designing or improving a process. The first of seven Lean Six Sigma guiding principles is to focus on your customer's needs.

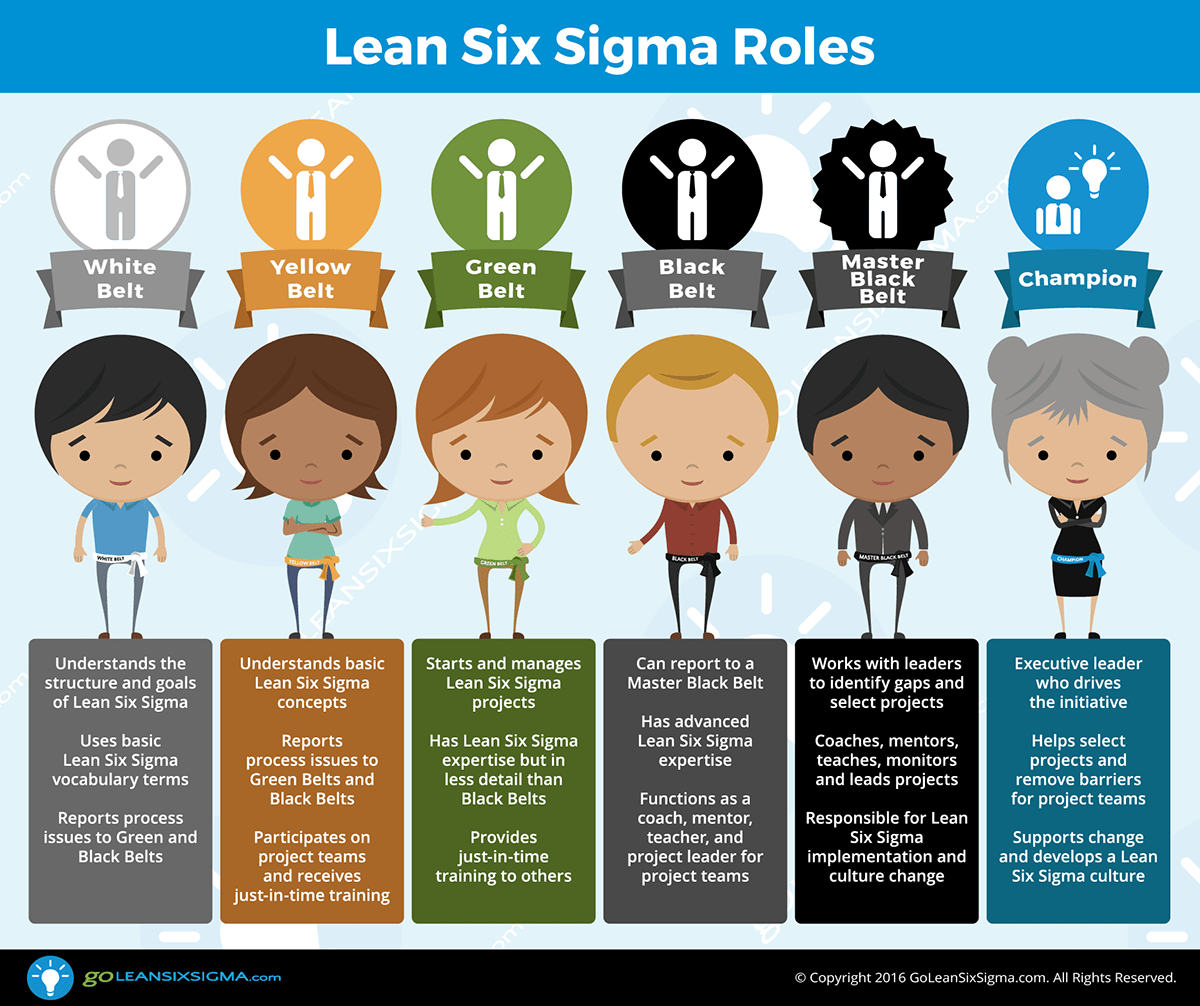

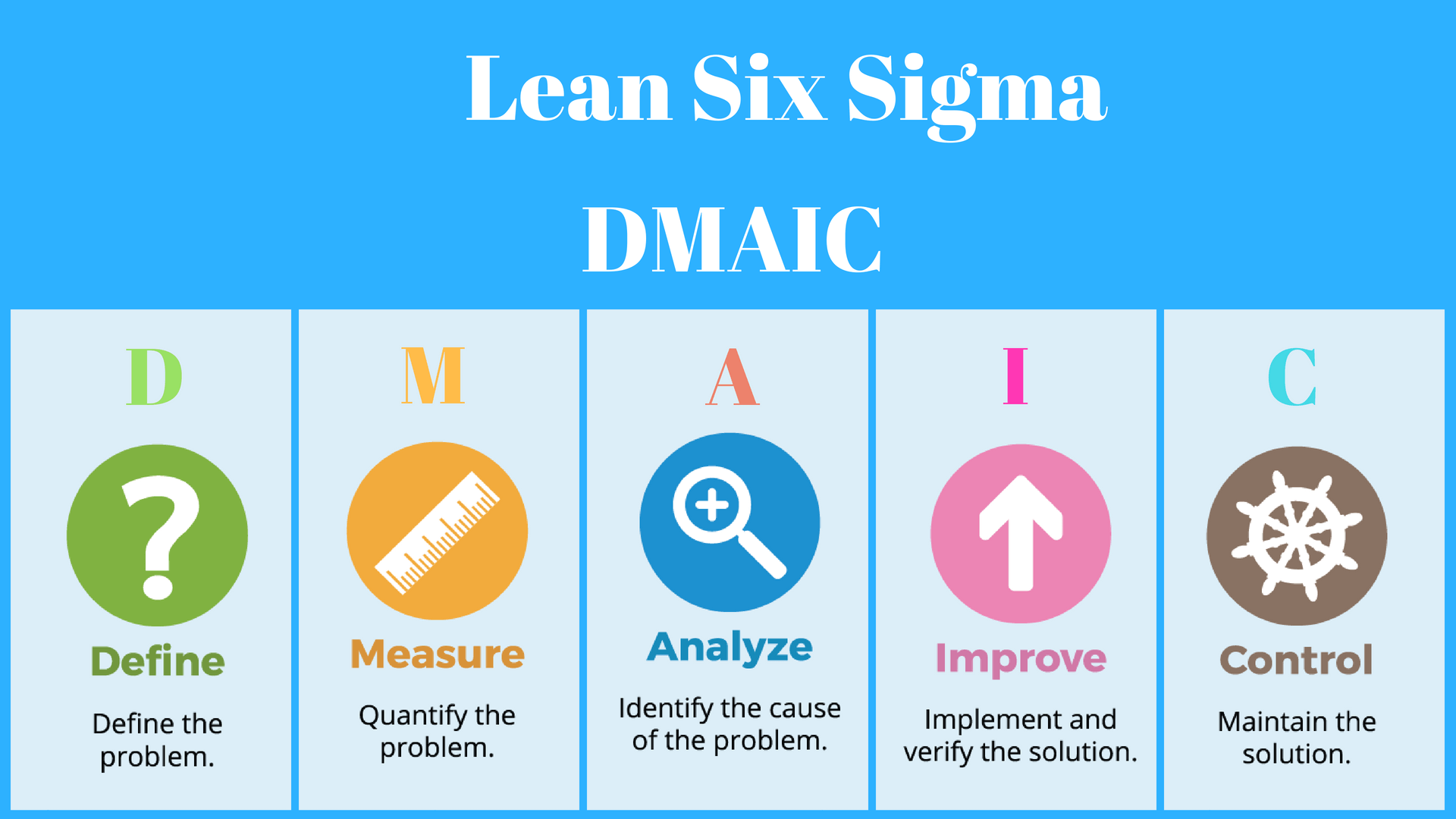

For a better understanding of the 7 principles of Lean Six Sigma, consider the explanation of each of the following points below. They can be applied to any process in any industry to achieve continuous improvement. These principles are designed to help organizations achieve their desired outcomes by eliminating waste and reducing variation. Undertake Improvements in a Systematic Process.There are seven Lean Six Sigma principles: These functions are carried out successively and are known as Six Sigma principles. Finally, the process must be monitored and controlled to maintain the improvements. Once the issues have been identified, they can be fixed or improved. They then must collect and analyze data to identify any errors or problems. To achieve Six Sigma, businesses must establish a clear goal or target. DMADV (Define, Measure, Analyze, Design, Verify) is a design methodology used when creating or improving a process. DMAIC (Define, Measure, Analyze, Improve, Control) is an improvement methodology used when a process needs to meet desired performance levels. There are two Six Sigma methodologies: DMAIC and DMADV. Moreover, lean Six Sigma concepts and principles become clearer and more precise during the Lean Six Sigma Green Belt Certification training. The concept uses key principles of Six Sigma to reduce defects and increase the profitability of a business. Six Sigma is a data-driven approach that seeks to find and eliminate errors to improve quality and efficiency. The Six Sigma principles are guidelines that help organizations improve their business processes. Several Best Lean Six Sigma courses help students understand more about the Six Sigma lean concepts. With the help of Six Sigma and lean manufacturing principles, lean Six Sigma aims to reduce defects in a circle to less than 3.4 per million opportunities. Lean Six Sigma is a data-driven approach that relies on statistical methods to improve operations. It uses the best aspects to create a more efficient and effective business process. Lean Six Sigma combines the Lean and Six Sigma rules and methodologies. Six Sigma is typically implemented by organizations in a top-down fashion, with executive leadership championing the initiative and setting ambitious goals for the organization to achieve. Six Sigma works on the principle of including tools and techniques for process improvement, such as statistical analysis and process mapping. The Six Sigma approach seeks to reduce variation in process outputs by identifying and eliminating the root causes of defects. The name "Six Sigma" comes from the statistical term for standard deviation, which is a measure of how far a set of data points deviates from the mean. The Six Sigma methodology is a business improvement strategy aiming to produce near-perfect results by minimizing defects and maximizing efficiency.

0 kommentar(er)

0 kommentar(er)